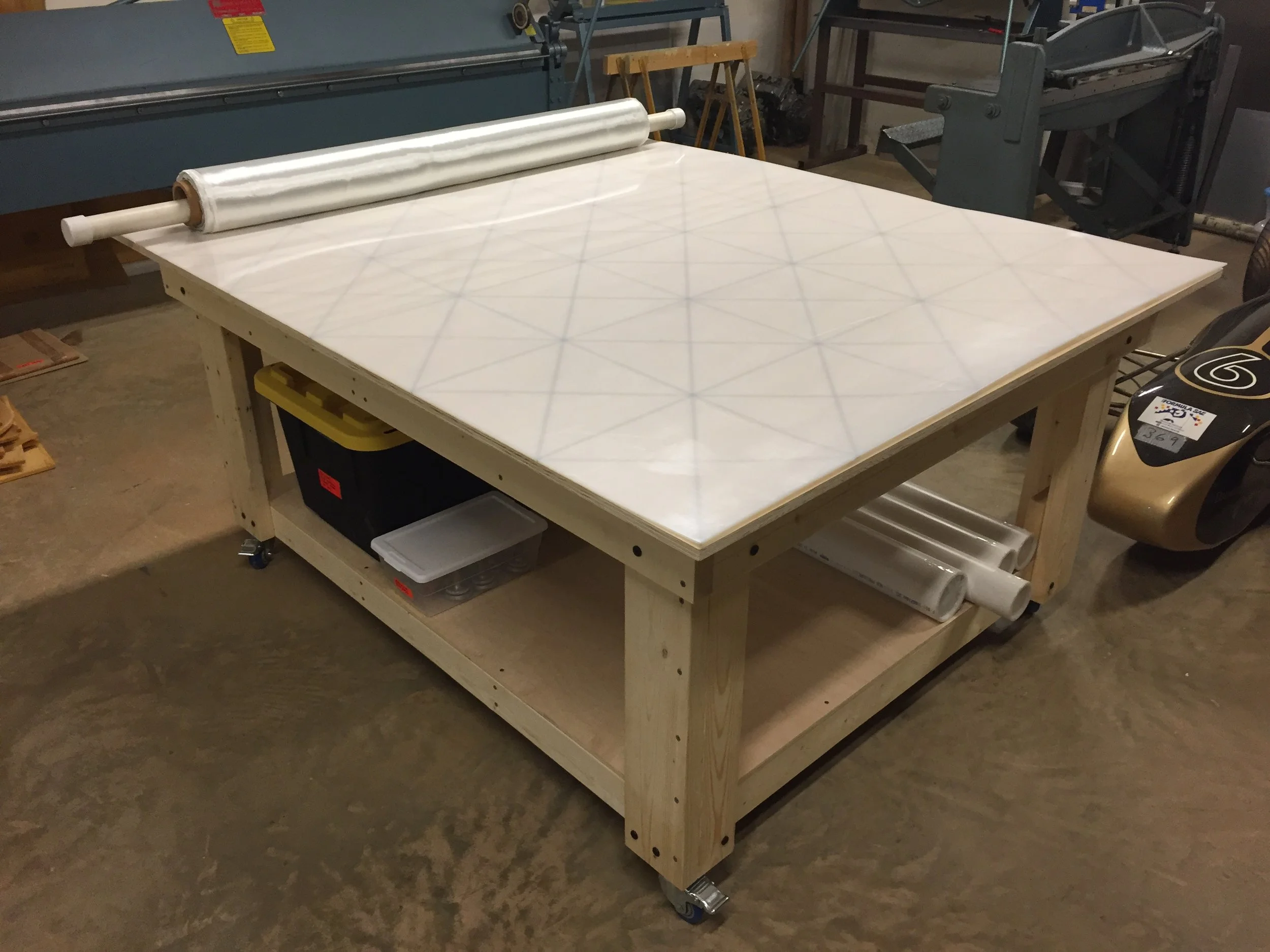

Composites Table - Final Details

With the basic structure finished, all that was left were the details.

I cut the 5x6ft HDPE top sheet on our shear at work since mine only cuts up to 52".

I made the guide lines on the bottom side so the top could be cleaned with solvent without removing the lines.

I debated gluing or screwing the top down, but didn't like the thought of exposed screw heads or glue that would deteriorate over time. So I decided to make an edge band out of .06" 3003 Aluminum.

Here's a test piece of the edge band to get the bend dimensions dialed in.

I mitered the corners and tapped everything into place with a rubber mallet. No screws needed, the edge holds the HDPE tightly to the plywood.

The rolls are kept in PVC tubes, an idea I got from my buddy Gary DeHart.

I have one large roll of fiberglass that is too big to fit into a PVC tube so I made some arms to hold it.

Here's the finished product. Now it's time to start building the plane!