Corner Notcher Restoration

I won an auction for this corner notcher on eBay. The pictures looked good, but I didn’t really know what the condition would be. These things aren’t very popular anymore since most sheet metal cutting is done by laser or water jet, but if you need to make a few quick cuts, they’re hard to beat.

My in-laws picked up the notcher in Ohio. Upon arrival, it didn’t look too bad. The pivots weren’t sloppy, and the blades didn’t have any nicks or show signs of abuse.

First thing I did was take it apart.

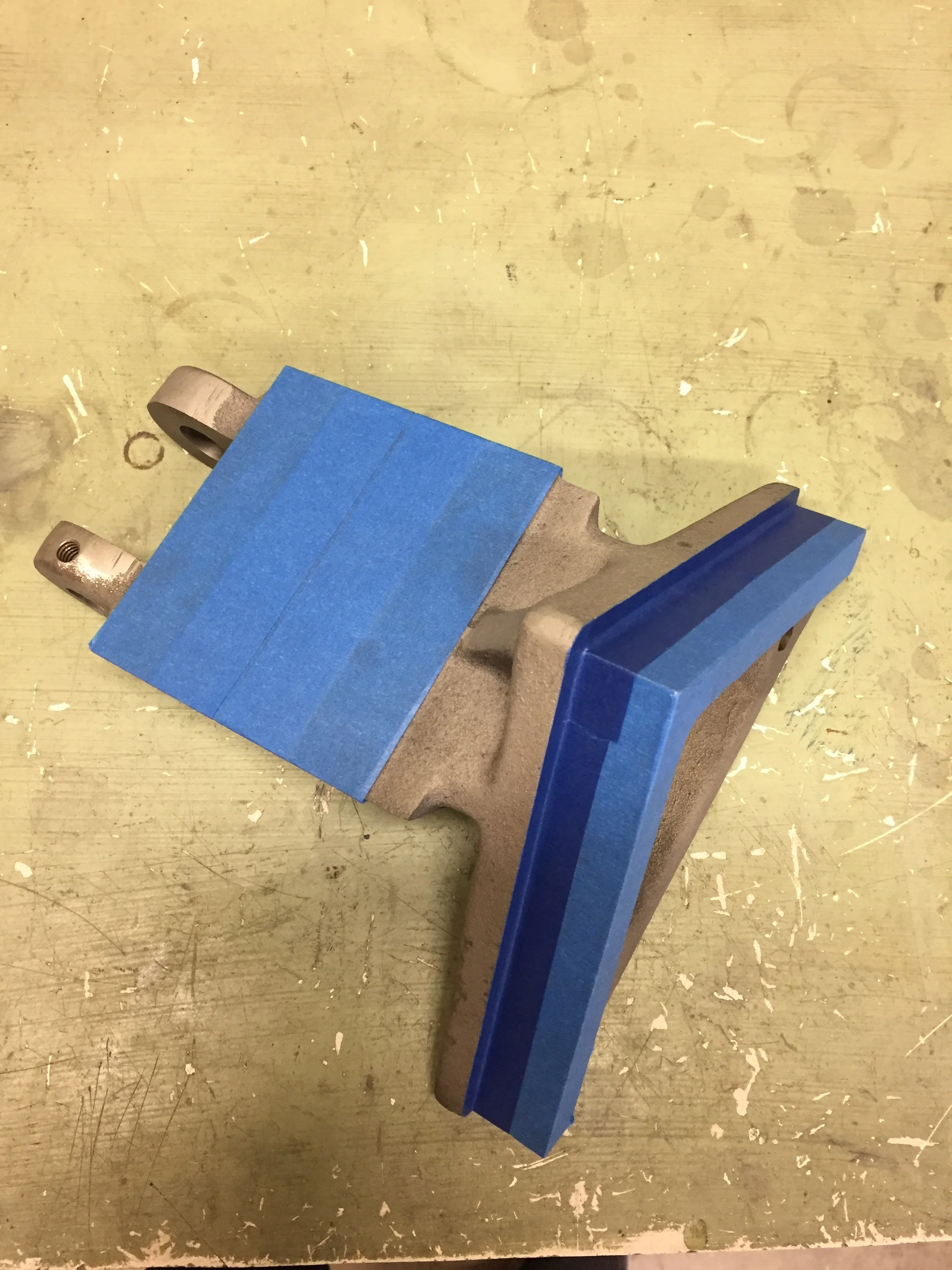

Everything got a good scrubbing in the parts washer, then blasted in the media blast cabinet.

After painting with Sherwin Williams Dimenso hammer tone paint, the parts were set out to dry in my “heated paint booth”.

I had the blades sharpened by Charlotte Knife, good as new! After re-assembling, and adjusting the clearances, it cut perfectly.

I made a stand from 2x2x.065” steel, and an aluminum bin to catch the pieces from the back side of the cut.